Installation

Spangleyboards and Spangleystrips are so versatile they can be used on many different types of signs, displays, floats, art work and scenery backgrounds. They are easy to install on foamex, wood, sintra, plastic, metal and fabrics.

Now introducing our latest innovation- Spangleycurtains.

The clear acrylic backing panels of Spangleycurtains are specially designed to work with Spangleystrips in two unique ways:

- creating a lightweight, transparent disc curtain which can be hung from virtually anywhere or;

- the backing panels of Spangleycurtains can also be used to space and attach your strips quickly and easily to any substrate with no measuring and no fuss.

Spangleyboards

Spangleyboards backing panels are 25cm by 25cm, 8 rows x 8 columns holding a total of 64 discs. There are 16 Spangleyboards in one square meter (approx. 11 square feet)

Each individual Spangleyboard is pre-drilled for fixing screws or it can be glued to another substrate. If gluing, you should choose a fast tacking glue that dries quickly to a firm bond carefully following the manufacturer’s instructions. Test any glue first to confirm adhesion.

Spangleyboards can be easily cut to size or into individual strips by simply scoring the back with an Exacto-knife and snapping the board.

Aluminium pins are pre-moulded into the panels. After the backing panel is attached to the substrate, the coloured reflective disc slips over the pin-head and clicks into place.

Spangleyboards are shipped with their discs separate from the backing boards. It will take one person about one hour to attach the discs for one square meter of Spangleyboards; longer for a complicated design.

Spangleystrips

Spangleystrips can be stapled, taped or glued to a variety of backing materials. Spangleystrips come with their discs pre-attached and the strips can be easily cut to size for any kind of job.

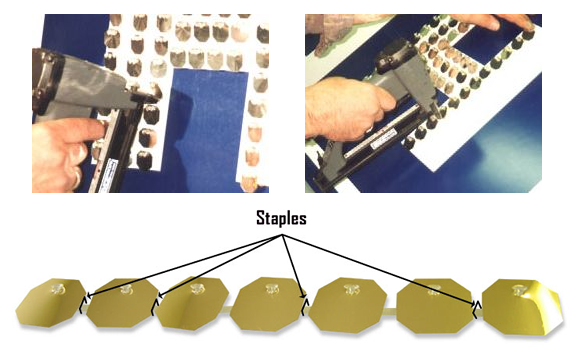

Stapling

Spangleys can be stapled onto wood or any surface which staples can penetrate. Be sure to use rust-proof (stainless steel) staples for outdoor applications. Stapling is the fastest and most cost efficient way of installing Spangleys. With a power staple gun, 80 to 120 lineal feet of Spangleystrips can be installed in one hour.

- For a rapid and exact installation, you may want to rule lines with chalk or use a hand held spacer.

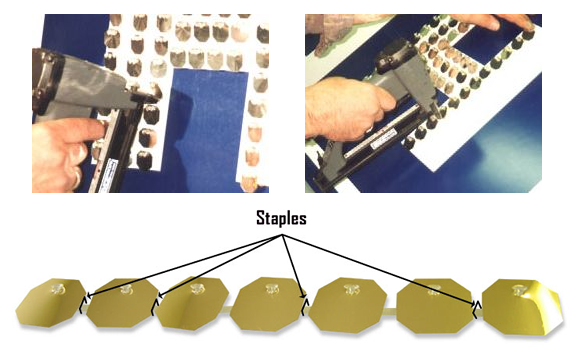

- With the power stapler, straddle the backing strip and staple about 3 or 4 staples per strip.

- When stapling Spangleys, have the backing strips go either in a horizontal direction (i.e. install Spangleys from the top to the bottom) or in a vertical direction (install Spangleys from the left to the right).

- Letters should be at least 25-30 cm (10 to 12 inches) high and the stroke should take at least two rows of Spangleys.

- Space the small disc strips about 2.5cm / 1 inch on centre. (So the discs don’t touch – Then the wind will be able to move them)

- Space the large disc strips about 4.5cm / 1-3/4 inches on centre.

- Never let the discs hang over the painted copy.

Taping

If taping Spangleystrips, use a high quality, strong bonding, all weather durable, double sided tape.

Gluing

When using glue, we advise you to follow carefully the instructions of the glue manufacturer. As there are many excellent adhesives on the market choose the glue to fit the specific requirements of the job. In most cases, choose a fast tacking glue that dries quickly to a firm bond. Test any glue first to confirm adhesion.

SPANGLEYCURTAINS

Creating a lightweight, transparent disc curtain

The Spangleycurtain backing panels attach together using the to create a lightweight disc backdrop which appears to hang weightlessly allowing light to pass through the curtain and create extra shimmer and sparkle.

⦁ Go around the edge spacing holes with a paperclip or pin to ensure any excess plastic has been cleared.

⦁ Align two backing panels by overlapping their edge holes.

⦁ Attach the two backing panels together with the tie clips provided via each pair of edge holes. Alternatively a quick drying glue or clear double-sided tape can be used. Line up the holes to ensure perfect alignment as shown.

IMPORTANT NOTE:

Spangleycurtains can be installed so that the Spangleystrips run horizontally or vertically. There is a larger gap between the pre-cut slots on one of the long edges of the backing panel. These larger edges need to be used in the same direction. If hanging the strips vertically these larger edges must be at the bottom of each panel. This allows the discs on the discs on the strips to hang down without overlapping.

- Repeat steps in order to attach further panels together and cut off any excess from the tie clips.

- Once assembled, the Spangleystrips can be easily attached to the backing panels by slotting each strip into the pre-cut slots.

- Different coloured strips can be used to create patterns or to change the display without needing to change the backing panels or individual discs can be removed and replaced with different coloured discs to make more intricate patterns.

- Backing panels can then be hung or attached via double-ended hooks or other POS furniture using the top edge holes. To purchase, see for instance:

http://www.sign-holders.co.uk/Sign-fixings/Hanging-wire-systems/POS-hanging-systems/c-1-44-151-161/ or https://www.ukpos.com/display-accessories-and-fixings/fixings-hooks-and-suction-cups

Spacing your Spangleystrips on a solid substrate

The backing panels of Spangleycurtains can also be used to space and attach your strips quickly and easily to any substrate- no measuring and no fuss.

⦁ Attach your strips to the backing panel by slotting each strip into the pre-cut slots. NOTE: This must be done first, before attaching the panel to your substrate or there will not be enough space behind the panel to insert your strips into the pre-cut slots.

⦁ The panels and strips can then be easily attached to your substrate with staples, screws or nails. We recommend power staples across the strip to ensure strips do not come loose, especially if using outdoors.

⦁ Line up and overlap the backing panels so that the edge holes line up in order to ensure perfect alignment.

⦁ Repeat as required. Panels can easily be cut if a smaller section is required.

⦁ For spaces less than a full strip in length, Spangleystrips can be attached directly to the substrate without a clear backing panel via staples or glue in the usual way (see above).

IMPORTANT NOTE:

Spangleycurtains can be installed so that the Spangleystrips run horizontally or vertically. There is a larger gap between the pre-cut slots on one of the long edges of the backing panel. These larger edges need to be used in the same direction. If hanging the strips vertically these larger edges must be at the bottom of each panel. This allows the discs on the discs on the strips to hang down without overlapping.

Installation

Spangleyboards and Spangleystrips are so versatile they can be used on many different types of signs, displays, floats, art work and scenery backgrounds. They are easy to install on foamex, wood, sintra, plastic, metal and fabrics.

Spangleyboards

Spangleyboards backing panels are 25cm by 25cm, 8 rows x 8 columns holding a total of 64 discs. There are 16 Spangleyboards in one square meter (approx. 11 square feet)

Each individual Spangleyboard is pre-drilled for fixing screws or it can be glued to another substrate. If gluing, you should choose a fast tacking glue that dries quickly to a firm bond carefully following the manufacturer�s instructions. Test any glue first to confirm adhesion.

Spangleyboards can be easily cut to size or into individual strips by simply scoring the back with an Exacto-knife and snapping the board.

Aluminium pins are pre-moulded into the panels. After the backing panel is attached to the substrate, the coloured reflective disc slips over the pin-head and clicks into place. Spangleyboards are shipped with their discs separate from the backing boards. It will take one person about one hour to attach the discs for one square meter of Spangleyboards; longer for a complicated design.

Spangleystrips

Spangleystrips can be stapled, taped or glued to a variety of backing materials. Spangleystrips come with their discs pre-attached and the strips can be easily cut to size for any kind of job.

Stapling

Spangleys can be stapled onto wood or any surface which staples can penetrate. Be sure to use rust-proof (stainless steel) staples for outdoor applications. Stapling is the fastest and most cost efficient way of installing Spangleys. With a power staple gun, 80 to 120 lineal feet of Spangleystrips can be installed in one hour.

- For a rapid and exact installation, you may want to rule lines with chalk or use a hand held spacer.

- With the power stapler, straddle the backing strip and staple about 3 or 4 staples per strip.

- When stapling Spangleys, have the backing strips go either in a horizontal direction (i.e. install Spangleys from the top to the bottom) or in a vertical direction (install Spangleys from the left to the right).

- Letters should be at least 25 � 30 cm (10 to 12 inches) high and the stroke should take at least two rows of Spangleys.

- Space the small disc strips about 2.5cm / 1 inch on centre. (So the discs don’t touch – Then the wind will be able to move them)

- Space the large disc strips about 4.5cm / 1-3/4 inches on centre.

- Never let the discs hang over the painted copy.

Taping

If taping Spangleystrips, use a high quality, strong bonding, all weather durable, double sided tape.

Gluing

When using glue, we advise you to follow carefully the instructions of the glue manufacturer. As there are many excellent adhesives on the market choose the glue to fit the specific requirements of the job. In most cases, choose a fast tacking glue that dries quickly to a firm bond. Test any glue first to confirm adhesion.

In Europe contact:

Langley Brooke Ltd

42 Greenwich Way

Waltham Abbey

Essex

EN9 3YS

Phone: +44(0)203 3686150

Mobile: +44 (0) 7747866300

Email: Click Here!

In North America contact:

Superior Signs

1502-1995 Beach Ave.

Vancouver, B.C., Canada

V6G 2Y3

Phone: +1 (604) 209-5603

Fax: +1 (604) 944-7336

Email: Click Here!

Web: www.spangleys.com